Scalable-automation press brakes

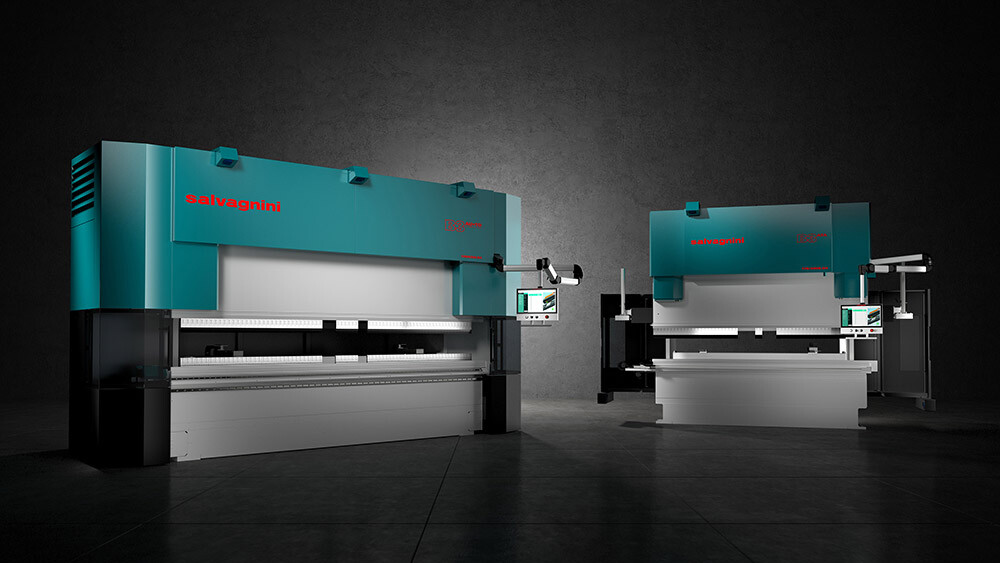

The ideal press brake for dynamic production, the B3 was designed by combining the features and benefits of electric and hydraulic press brakes with Salvagnini’s in-depth knowledge of automation, software, mechanics and electronics.

Change perspective, think results

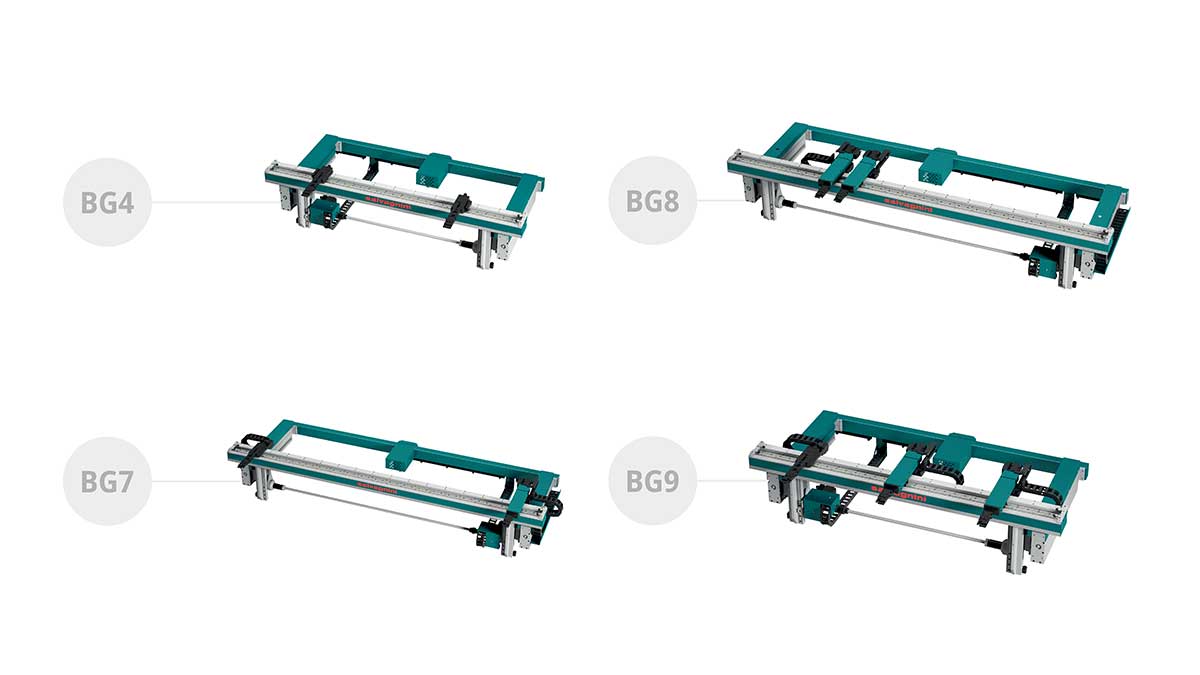

Regardless of the level of automation chosen from the four available, the B3 remains the solution with the smallest footprint currently available on the market.

Product overview

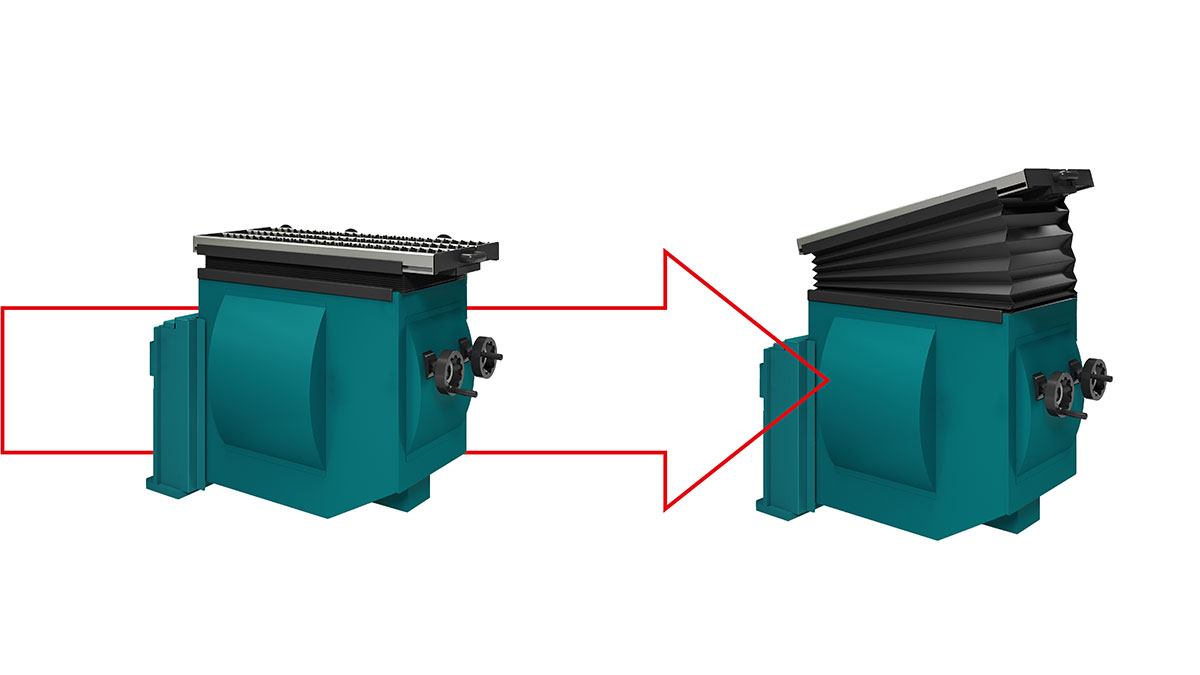

AMS: angle measurement system

Laser system that detects variations in the bending angle due to sheet metal springback. Angle measurement can even be performed in a single point, regardless of the length of the press brake, for shorter cycles. It allows measurement recording and active monitoring for greater productivity.

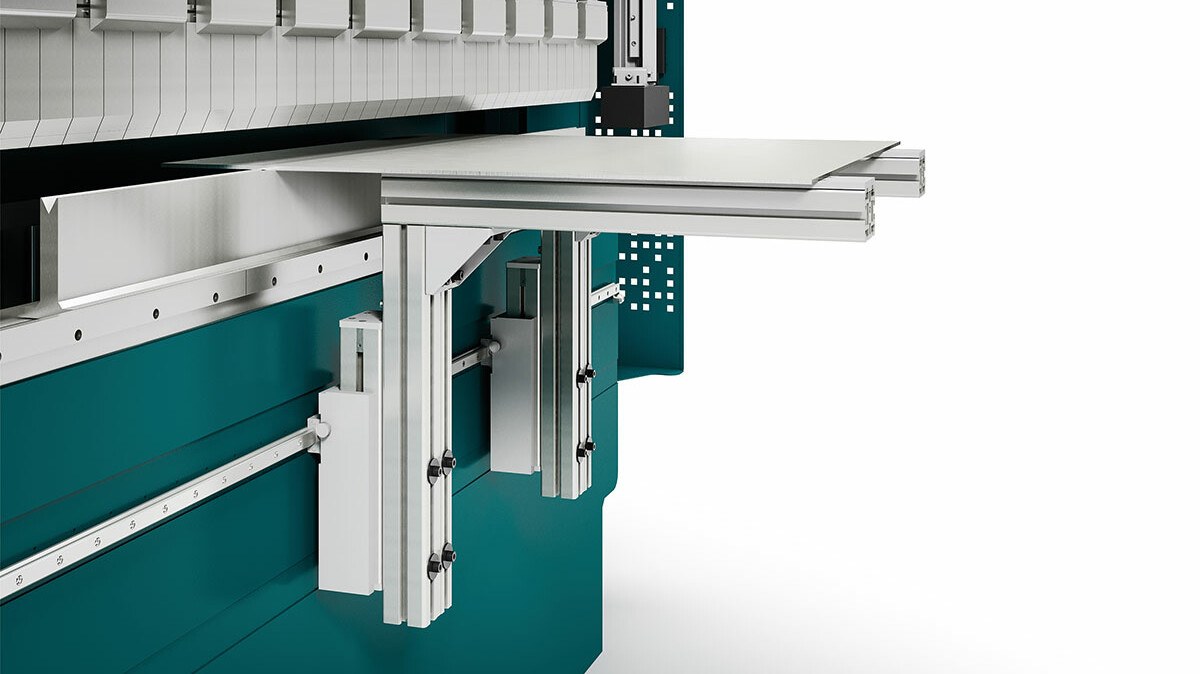

S-CROWNING

The adaptive mechanical crowning system ensures consistent bending along the entire bending length, even if the parameters change, without operator intervention.

Direct Drive

Ram movements are driven by two independent direct-drive brushless motors, which allow both fast approach and fast return movements to be achieved, with speeds as high as 250 mm/s.

Industry 4.0

Digital transformation and Industry 4.0 are key topics for staying competitive on the market. When adopted, they can implement and manage complex, integrated, highly automated high-performance systems, and can help to develop simple solutions that require no structural changes to the production layout, making the world of smart manufacturing much more accessible.

Intelligent system, constant quality

Practically everything you ever wanted to know about the B3 press brake, satisfactorily explained.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the press brake. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Technical data

| Models | 80/2000 | 100/3000 | 135/3000 | 135/4250 | 170/3000 | 170/3000XL |

| Maximum bending force (Tons) | 80 | 100 | 135 | 135 | 170 | 170 |

| Table length (mm) | 2040 | 3060 | 3060 | 4250 | 3060 | 3060 |

| Distance between side frames (mm) | 1740 | 2640 | 2640 | 3640 | 2640 | 2650 |

| Throat depth (mm) | 350 | 435 | 435 | 435 | 435 | 520 |

| Maximum speed (mm/s) | 250 | 250 | 250 | 250 | 250 | 180 |

| Bending speed* (mm/s) | 15 | 15 | 15 | 15 | 15 | 15 |

| Maximum stroke (mm) | 300 | 300 | 350 | 350 | 350 | 450 |

| Table-ram distance (mm) | 550 | 550 | 600 | 600 | 600 | 700 |

| Total lenght (mm) | 3200 | 4270 | 4310 | 5310 | 4310 | 4360 |

| Total width (mm) | 1875 | 1725 | 1735 | 1735 | 1735 | 2080 |

| Total height (mm) | 3025 | 3025 | 3295 | 3295 | 3295 | 3705 |

| Average consumption (kWh) | 1 | 1 | 1.5 | 1.5 | 2 | 2 |

| Mass (kg) | 6200 | 8600 | 11700 | 13500 | 11700 | 17000 |

| Models | 170/4250 | 170/4250XL | 170/5100XL | 240/3000 | 240/4250 | 240/5100 | 240/6100 |

| Maximum bending force (Tons) | 170 | 170 | 170 | 240 | 240 | 240 | 240 |

| Table length (mm) | 4250 | 4250 | 5100 | 3060 | 4250 | 5100 | 6100 |

| Distance between side frames (mm) | 3640 | 3620 | 4620 | 2650 | 3620 | 4620 | 5600 |

| Throat depth (mm) | 435 | 520 | 520 | 520 | 520 | 520 | 520 |

| Maximum speed (mm/s) | 250 | 220 | 180 | 220 | 220 | 220 | 180 |

| Bending speed* (mm/s) | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Maximum stroke (mm) | 350 | 450 | 450 | 450 | 450 | 450 | 450 |

| Table-ram distance (mm) | 600 | 700 | 700 | 700 | 700 | 700 | 700 |

| Total lenght (mm) | 5310 | 5330 | 6330 | 4360 | 5330 | 6330 | 7400 |

| Total width (mm) | 1735 | 2080 | 2080 | 2080 | 2080 | 2080 | 2080 |

| Total height (mm) | 3295 | 3705 | 3705 | 3705 | 3705 | 3705 | 3705 |

| Average consumption (kWh) | 2 | 2 | 2 | 2.5 | 2.5 | 2.5 | 2.5 |

| Mass (kg) | 13500 | 19400 | 21500 | 17000 | 19400 | 21500 | 23500 |

| Models | 320/3000 | 320/4250 | 320/5100 | 400/4250 | AU-TO 170/4250 | AU-TO 240/4250 | AU-TO 320/4250 |

| Maximum bending force (Tons) | 320 | 320 | 320 | 400 | 170 | 240 | 320 |

| Table length (mm) | 3060 | 4250 | 5100 | 4250 | 4250** | 4250 | 4250** |

| Distance between side frames (mm) | 2630 | 3600 | 4600 | 3600 | 3640 | 3620 | 3600 |

| Throat depth (mm) | 520 | 520 | 520 | 520 | 435 | 520 | 520 |

| Maximum speed (mm/s) | 220 | 220 | 220 | 220 | 250 | 220 | 220 |

| Bending speed* (mm/s) | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Maximum stroke (mm) | 450 | 450 | 450 | 450 | 350 | 450 | 450 |

| Table-ram distance (mm) | 700 | 700 | 700 | 700 | 600 | 700 | 700 |

| Total lenght (mm) | 4380 | 5350 | 6350 | 5350 | 5560 | 5560 | 5700 |

| Total width (mm) | 2085 | 2085 | 2085 | 2085 | 2170 | 2240 | 2245 |

| Total height (mm) | 3755 | 3755 | 3755 | 3755 | 3290 | 3690 | 3740 |

| Average consumption (kWh) | 3.5 | 3.5 | 3.5 | 3.5 | 2 | 2.5 | 3.5 |

| Mass (kg) | 21800 | 25000 | 30000 | 27000 | 15500 | 21600 | 27200 |

* Bending speed regulated by current standards. Salvagnini reserves the right to modify this data without prior notice.

** automatic tools set up L = 3060 mm