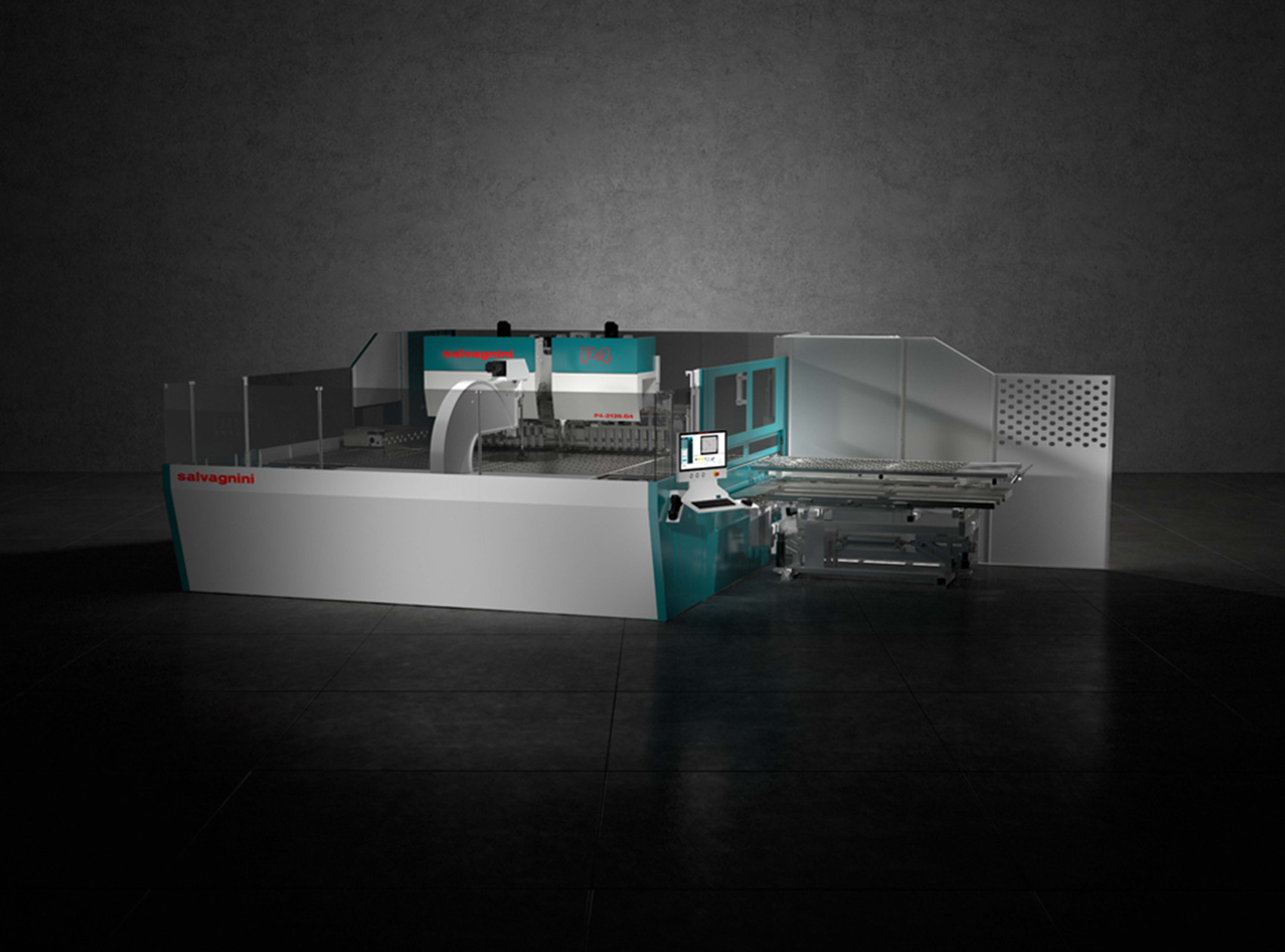

Automatic panel bender for versatile production

The P4 natively combines productivity, with its automatic bending and handling cycles, and flexibility, with its universal bending tools.

Product overview

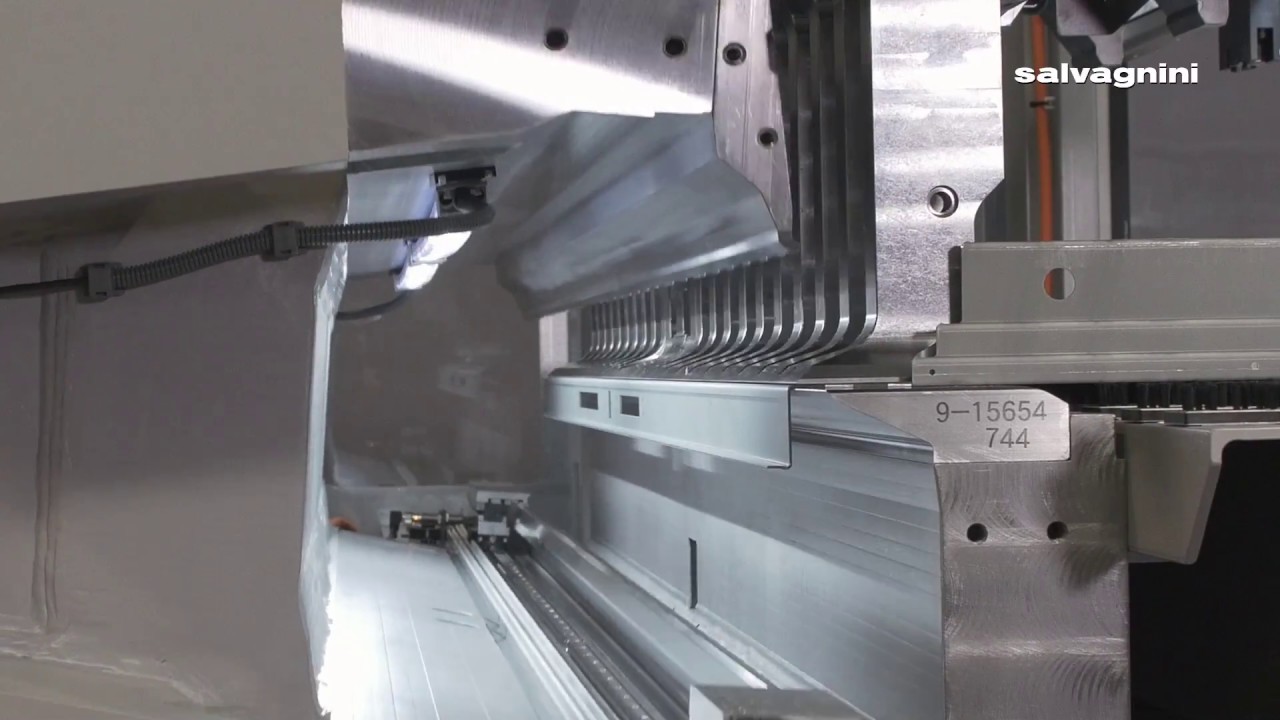

MAC3.0

MAC3.0 detects any differences in the mechanical characteristics of the material compared to their nominal value during the cycle, adapting the movements of the bending unit and the manipulator to compensate them.

Industry 4.0

Digital transformation and Industry 4.0 are key topics for staying competitive on the market. When adopted, they can implement and manage complex, integrated, highly automated high-performance systems, and can help to develop simple solutions that require no structural changes to the production layout, making the world of smart manufacturing much more accessible.

Made-to-measure modularity

P4 can be fed manually or automatically, picking the sheets up from one or more sheet metal packs and feeding the machine in masked time. P4 can also be equipped with different unloading devices, manual or robotized.

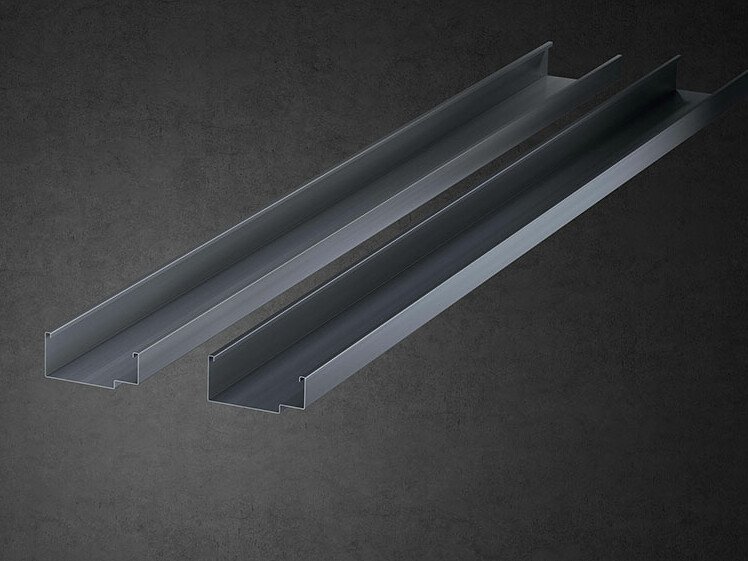

Intelligent system, constant quality

Practically everything you ever wanted to know about the P4 panel bender, satisfactorily explained.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the panel bender. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Technical data

| Model | P4-2120 | P4-2226 | P4-2520 |

| Maximum length of incoming sheet (mm) | 2495 | 2815 | 3050 |

| Maximum width of incoming sheet (mm) | 1524 | 1524 | 1524 |

| Maximum diagonal that can be rotated (mm) | 2500 | 2820 | 3200 |

| Maximum bending force (kN) | 330 | 590 | 660 |

| Maximum clamping force (kN) | 530 | 635 | 1060 |

| Maximum bending length (mm) | 2180 | 2200 | 2500 |

| Maximum bending height (mm) | 203 | 260 | 203 |

| Minimum thickness (mm) | 0.5 | 0.5 | 0.5 |

| Maximum thickness and bending angle steel, UTS 410 N/mm2 (mm) | 3.2 (±90°) | 3.2 (±90°) | 3.2 (±90°) |

| Maximum thickness and bending angle stainless steel, UTS 660 N/mm2 (mm) | 2.5 (±90°) | 2.5 (±90°) | 2.5 (±90°) |

| Maximum thickness and bending angle aluminium, UTS 265 N/mm2 (mm) | 4.0 (±120°) | 4.0 (±120°) | 4.0 (±120°) |

| Model | P4-2535 | P4-2720 | P4-3126 |

| Maximum length of incoming sheet (mm) | 3495 | 3050 | 3495 |

| Maximum width of incoming sheet (mm) | 1524 | 1524 | 1524 |

| Maximum diagonal that can be rotated (mm) | 3500 | 3200 | 3500 |

| Maximum bending force (kN) | 660 | 660 | 625 |

| Maximum clamping force (kN) | 1060 | 1060 | 825 |

| Maximum bending length (mm) | 2500 | 2750 | 3100 |

| Maximum bending height (mm) | 350 | 203 | 260 |

| Minimum thickness (mm) | 0.5 | 0.5 | 0.5 |

| Maximum thickness and bending angle steel, UTS 410 N/mm2 (mm) | 2.5 (±90°) | 3.2 (±90°) | 3.2 (±90°) |

| Maximum thickness and bending angle stainless steel, UTS 660 N/mm2 (mm) | 2.1 (±90°) | 2.5 (±90°) | 2.5 (±90°) |

| Maximum thickness and bending angle aluminium, UTS 265 N/mm2 (mm) | 3.2 (±120°) | 4.0 (±120°) | 4.0 (±120°) |

| Model | P4-3220 | P4-4020 | ||

| Maximum length of incoming sheet (mm) | 3850 | 4000 | ||

| Maximum width of incoming sheet (mm) | 1524 | 1524 | ||

| Maximum diagonal that can be rotated (mm) | 4000 | 4280 | ||

| Maximum bending force (kN) | 660 | 660 | ||

| Maximum clamping force (kN) | 1060 | 1060 | ||

| Maximum bending length (mm) | 3200 | 400-3200 | 3200-3850 | 3850-4000 |

| Maximum bending height (mm) | 203 | 203 | ||

| Minimum thickness (mm) | 0.5 | 0.5 | ||

| Maximum thickness and bending angle steel, UTS 410 N/mm2 (mm) | 3.2 (±90°) | 3.2 (±90°) | 2.5 (±125°) | 1.6 (±130°) |

| Maximum thickness and bending angle stainless steel, UTS 660 N/mm2 (mm) | 2.5 (±90°) | 2.5 (±90°) | 2.5 (±90°) | 1.3 (±120°) |

| Maximum thickness and bending angle aluminium, UTS 265 N/mm2 (mm) | 4.0 (±120°) | 4.0 (±120°) | 4.0 (±120°) | 2.5 (±125°) |

Values refer to a standard machine. Salvagnini reserves the right to modify this data without warning.